Electric Servo Press

Equipped with a rigid column and a smooth processing surface. It features easy installation and requires no additional devices to fasten or adjust.

Based on different applications, users can choose optional area sensors, heating systems, as well as customized software for data transmission and monitoring.

Product Introduction

Features & Benefits

- High repeatability and multiple strokes

- Precise press and flexible control

- Seamless hardware and software integration for high efficien

- Multiple processes adaptable to changeovers

- Multiple machine connection and remote control

- Robust design

Parameter

| Specification | Specification | Specification | Specification |

| YHC-50-100kgs | YHC-100-500kgs | YHC-1-2T | YHC-3T |

| Desktop C frame | Desktop C frame | Desktop C frame | Desktop C frame |

| 1/pressure mode—2/position mode—3/position force mode | 1/pressure mode—2/position mode—3/position force mode | 1/pressure mode—2/position mode—3/position force mode | 1/pressure mode—2/position mode—3/position force mode |

| 86KG±5KG | 95KG±5KG | 380KG±15KG | 480KG±15KG |

| ≥100mm | ≥150mm | ≥150mm | ≥150mm |

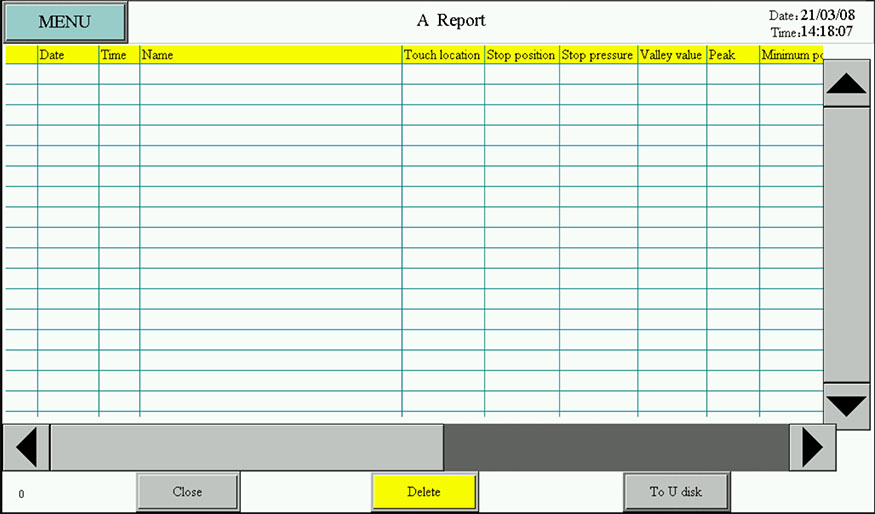

| USB (real time) | USB (real time) | USB (real time) | USB (real time) |

| 1N | 1N | 1N | 1N |

| 0.001mm | 0.001mm | 0.001mm | 0.001mm |

| ±zone location | ±zone location | ±zone location | ±zone location |

| ±zone location | ±zone location | ±zone location | ±zone location |

| save and call | save and call | save and call | save and call |

| ≤0.01mm | ≤0.01mm | ≤0.01mm | ≤0.01mm |

| ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm |

| 1%FS | 1%FS | 1%FS | 1%FS |

| more than 100 sets | more than 100 sets | more than 100 sets | more than 100 sets |

| range 0.02mm≤80mm | range 0.02mm≤80mm | range 0.02mm≤80mm | range 0.02mm≤80mm |

| range 0.02mm≤80mm | range 0.02mm≤80mm | range 0.02mm≤80mm | range 0.02mm≤80mm |

| range 0.05mm≤150mm | range 0.05mm≤150mm | range 0.05mm≤150mm | range 0.05mm≤150mm |

| upper/lower 100MM/S (adjustable) | upper/lower 100MM/S (adjustable) | upper/lower 100MM/S (adjustable) | upper/lower 100MM/S (adjustable) |

| 0.1-50mm/s (adjustable) | 0.1-50mm/s (adjustable) | 0.1-50mm/s (adjustable) | 0.1-50mm/s (adjustable) |

| 0.75KW | 0.75KW | 1-2KW | 3KW |

| computer ash (powder baking paint) | computer ash (powder baking paint) | computer ash (powder baking paint) | computer ash (powder baking paint) |

| Item | Specification | Specification | Specification | Specification |

| YHC-5T | YHC-8-20T | YH4-5T | YH4-8-20T | |

| Model | Desktop C frame | Desktop C frame | four column type | four column type |

| Pressing mode | 1/pressure mode—2/position mode—3/position force mode | 1/pressure mode—2/position mode—3/position force mode | 1/pressure mode—2/position mode—3/position force mode | 1/pressure mode—2/position mode—3/position force mode |

| Equipment weight | 1100KG±50KG | 1500KG±50KG | 1100KG±50KG | 1600KG±50KG |

| Maximum stroke | ≥150mm | ≥150mm | ≥150mm | ≥150mm |

| Data storage | USB (real time) | USB (real time) | USB (real time) | USB (real time) |

| Pressure resolution | 1N | 1N | 1N | 1N |

| Displacement resolution | 0.001mm | 0.001mm | 0.001mm | 0.001mm |

| Pressure judgment | ±zone location | ±zone location | ±zone location | ±zone location |

| Location judgment | ±zone location | ±zone location | ±zone location | ±zone location |

| Press-fitting program formula | save and call | save and call | save and call | save and call |

| Displacement accuracy | ≤0.01mm | ≤0.01mm | ≤0.01mm | ≤0.01mm |

| Displacement repetition accuracy | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm |

| Pressure accuracy | 1%FS | 1%FS | 1%FS | 1%FS |

| Program capacity | more than 100 sets | more than 100 sets | more than 100 sets | more than 100 sets |

| Flatness of upper indenter | range 0.02mm≤80mm | range 0.02mm≤80mm | range 0.02mm≤80mm | range 0.02mm≤80mm |

| Relative parallelism of upper and lower worktables | range 0.02mm≤80mm | range 0.02mm≤80mm | range 0.02mm≤80mm | range 0.02mm≤80mm |

| Verticality | range 0.05mm≤150mm | range 0.05mm≤150mm | range 0.05mm≤150mm | range 0.05mm≤150mm |

| The fastest speed of spindle | upper/lower 100MM/S (adjustable) | upper/lower 100MM/S (adjustable) | upper/lower 100MM/S (adjustable) | upper/lower 100MM/S (adjustable) |

| press-fitting speed | 0.1-50mm/s (adjustable) | 0.1-50mm/s (adjustable) | 0.1-50mm/s (adjustable) | 0.1-50mm/s (adjustable) |

| Total power of equipment | 3-5KW | 7.5KW | 1-3KW | 3-7.5KW |

| Equipment appearance color | computer ash (powder baking paint) | computer ash (powder baking paint) | computer ash (powder baking paint) | computer ash (powder baking paint) |

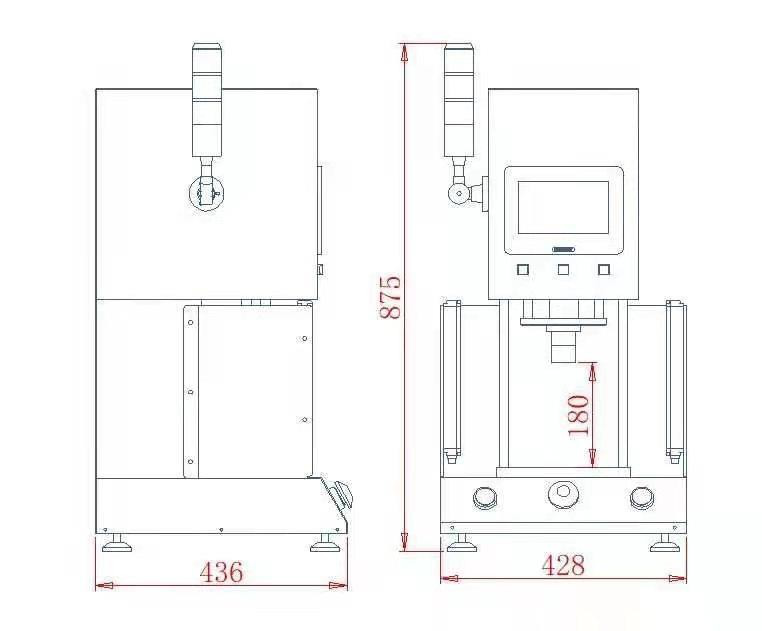

Dimensions

Product Application

1: Press-fitting of motor bearings

2: Press-fitting of the motor rotor

3: Press-fitting of automobile valve core

4: Press-fitting of motor shell

5: Press-fitting of automobile brake disc bearings

6: Press-fitting of motor gear

7: Press-fitting of bearing retainer for automobile direction assembly

8: Press-fitting of copper gaskets for automobile oil pipes

9: Press-fitting of automobile tubing head

Main Features

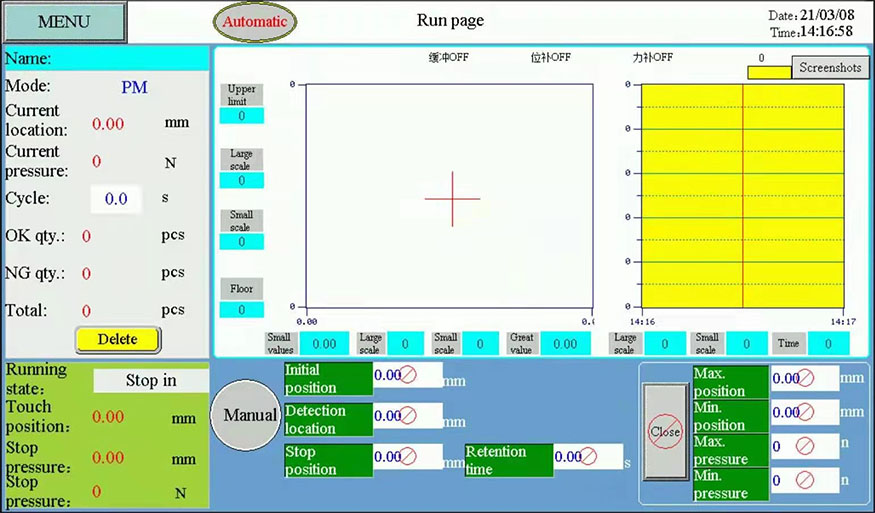

1. Position setting function: 1>Indenter position display, which can be set;

2>Press-fitting adjustable stroke: 0-150mm, controllable digital display actual press-fitting stroke,

3>Repeat accuracy: ±0.01mm;

2.Pressure setting function: 1>Display pressing pressure;

2>Set the upper limit of the pressure head pressure. When the press-fitting pressure is greater than the upper limit pressure, the upper pressure head immediately returns and alarms;

3>Set the lower limit of the pressure head pressure. When the press-fitting pressure is less than the lower limit pressure, the upper pressure head will return immediately and alarm;

4>Pressure display: 0-50000N, pressure curve real-time display.

5. It can store more than 100 sets of workpiece programs, which can be called at any time, and it has the function of parameter setting.

industry fields

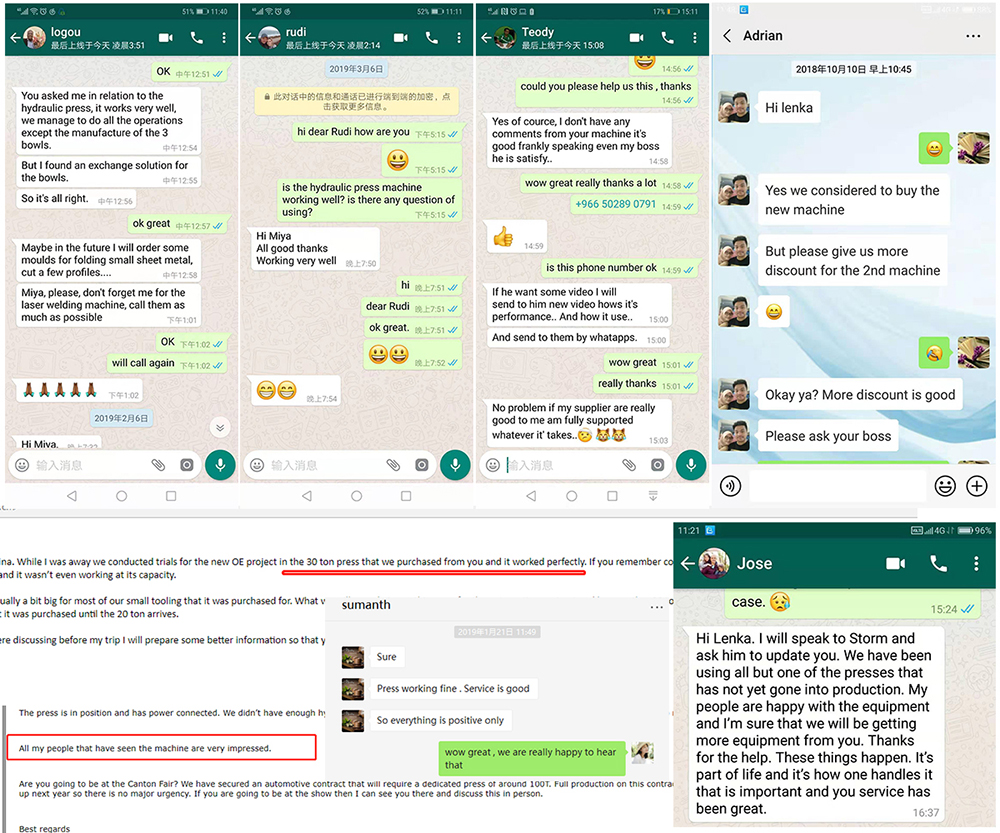

Why so many famous brand company cooperate with us ?

1.Our factory have specialized in independent development and producing hydraulic press for 19 years. So the product is stable and high quality.

2. Machine body, we use bending structure , much stronger than the common welding structure .

3. Oil pipe, we use Clip-on structure , much tight than common welding structure. Prevent oil leakage.

4. We take integrated oil manifold block, much easier to check machine and repair machine.

5.The main components are imported from Japan and Taiwan . So the quality is near the Japan production, but the unit price is lower than Japan production.

6.Our factory can offer full set line service, such as the mould,process technology, and other relative machines.

Certificate:

YIHUI Hydraulic press with servo system,can bring you 10 kinds advantages as below:

1.Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2.English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% – 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.

(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

It means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service.

Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.